Hey there! Have you ever walked by a construction site and wondered how builders know exactly where to place everything—from walls, foundations, and even roads? Well, it all comes down to control lines construction. It’s a super important process that ensures buildings and other structures are built exactly where they’re supposed to be. To help you understand, we’re breaking it all down in the simplest way possible.

Stick with me, and soon, you’ll know what control lines are, why they’re so important, and even some methods builders use to create them! Plus, we’ll chat about real-world examples like the coastal construction control line. Fun, right? Okay, let’s get started!

First, What Are Control Lines?

Picture this. You’re drawing on a blank piece of paper, trying to recreate something you saw in a video game. To make sure your drawing is straight and proportional, you might use a ruler or some grid paper. Well, that’s sort of what control lines are for in construction.

Control lines are like invisible rulers or guidelines that help builders measure and map out exactly where things should go during construction layout. Think of them as the GPS for a construction site!

These lines make sure everything is properly aligned, both horizontally and vertically. Without them, buildings could end up leaning, uneven, and unsafe! Yikes, right?

Why Is Control Lines Construction so Important?

Imagine planning a huge birthday party but forgetting to arrange who will bring the cake or entertainment. Chaos, right? The same can happen in construction without proper site planning and control lines.

Here are three big reasons why control lines construction is a must:

- Accuracy: No one wants a crooked building. Control lines help ensure everything is precise, from floors to walls.

- Safety: Poor planning can lead to weak foundations or structures that collapse. Nobody wants that!

- Cost Efficiency: Mistakes in construction are expensive. With good planning and lines, you avoid costly errors.

Even famous landmarks like skyscrapers or bridges owe their beauty and stability to good control line methods!

Methods for Creating Control Lines

Now, you might be wondering, how do builders make these magical guidelines? Well, there are more than a few ways. Let’s identify three effective methods for control line construction so you can impress your friends later:

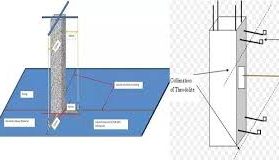

- Site Surveying Tools

Engineers use tools like laser levels and surveying tools to measure distances and angles accurately. It’s like using a high-tech ruler to ensure precision. - Construction Markings

This is where workers physically mark the lines onto the ground with chalk, paint, or stakes. These marks serve as guideposts for construction workers. - Coordinate Systems

Big projects, like creating a florida coastal construction control line map, use special GPS-based systems to map out where structures should go. This ensures that nothing overlaps or goes out of bounds.

By combining these methods with good old-fashioned project management, engineers can keep construction flowing smoothly. Amazing, right?

What’s the Deal With the Coastal Construction Control Line?

Ah, this one always gets questions. The coastal construction control line, or CCCL, isn’t just about buildings. It’s about protecting nature, too! Along coastlines in places like Florida or Alabama, these lines make sure construction stays safe and doesn’t harm the environment.

For example, in Florida, a florida coastal construction control line survey determines how far out to the seaward of the coastal construction control line buildings can go without damaging the delicate ecosystem. The florida coastal construction control line map is like a guide for both safety and sustainability. It helps builders know where they’re allowed to construct without messing up the beaches or wildlife.

That’s why there are rules like the coastal construction control line addendum to ensure everyone plays fair. Isn’t it cool how science and the environment come together?

Fun Fact! Fire Control Lines

Switching gears a bit, control lines aren’t just for buildings. Did you know they’re also used to fight wildfires? Yep! Firefighters create firebreaks or fire control lines to stop flames from spreading.

There are 7 variations of natural and constructed fire control lines, including digging trenches, clearing vegetation, or even using a mechanized piece of equipment to create barriers. These techniques save lives and protect property during wildfire season. Pretty heroic, huh?

Tools Builders Use for Control Lines

You can’t talk about control lines in construction without discussing tools. Builders use all sorts of gadgets for this process. Here’s a quick list of go-to tools for the job:

- Surveying tools like tripods and levels

- Alignment tools for making lines straight

- High-tech measurement techniques for precision

- Special engineering design software to visualize layouts

And then there’s the human factor. Along with tools, careful planning, and teamwork ensure all goes well. Teams use construction workflows to stay organized and follow construction codes for safety.

From Paper to Reality

It’s one thing to design a building and another to actually construct it. This is where architectural drawings, construction blueprints, and site benchmarks come into play. These documents act like the behind-the-scenes plans of your favorite movie. They guide teams on where to place building foundations and walls using both horizontal controls and vertical controls.

All that planning ensures perfection. It’s almost like solving a massive puzzle where each piece needs to fit perfectly.

Wrapping It All Up

Whoa, that was a lot of info, wasn’t it? But control lines construction is a fascinating topic once you break it down. It’s all about ensuring buildings are straight, safe, and secure. Plus, it connects us to nature and helps us tackle challenges like wildfires or coastal erosion.

Here’s a quick recap of what we covered:

- Control line basics and why they matter

- Construction precision tools, techniques, and layouts

- How the coastal construction control line protects both people and the environment

- Cool stuff like wildfire construction markings

Next time you see a construction site, think about all the hard work that goes into those neat and precise layouts. And who knows? Maybe someday you’ll help design buildings, too! Information, and regularly monitor and maintain the control lines.