In the realm of structural engineering, the efficiency and safety of building structures depend on the meticulous design and implementation of key elements, including stirrups in beams. Stirrups, also known as shear reinforcement, play a pivotal role in enhancing the structural integrity of beams by providing crucial support against shear forces. This article explores the significance, design considerations, and applications of stirrups in beam construction.

Understanding Stirrups in Beams:

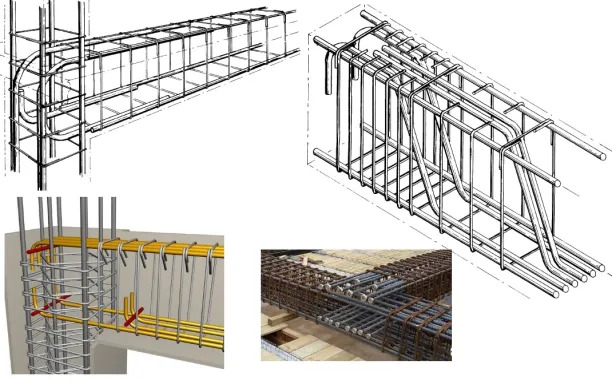

Stirrups are structural elements that reinforce beams by resisting shear forces and preventing diagonal cracking. They typically take the form of closed loops or ties and are positioned perpendicular to the longitudinal axis of the beam. Stirrups play a vital role in maintaining the equilibrium of forces within a beam, ensuring its stability and load-carrying capacity.

Shear Forces in Beams:

Beams are subjected to various forces, including bending and shear. Shear forces act parallel to the cross-section of a beam, attempting to slide one part of the beam relative to another. Without proper reinforcement, shear forces can lead to structural failure, manifested as diagonal cracks and potential collapse. Stirrups effectively counteract these shear forces, enhancing the beam’s ability to withstand applied loads.

Design Considerations for Stirrups:

The design of stirrups involves careful consideration of factors such as the magnitude of shear forces, the dimensions of the beam, and the properties of the materials used. Engineers determine the spacing, diameter, and configuration of stirrups based on structural analysis and code requirements to ensure the safe and efficient performance of the beam under various loading conditions.

Types of Stirrup Configurations:

Stirrups come in various configurations to suit different design and construction requirements. Common types include straight or bent ties, rectangular links, or spirals. The choice of configuration depends on factors such as the structural layout, the magnitude of shear forces, and the specific engineering standards governing the project.

Spacing and Placement:

The spacing between stirrups is a critical parameter in their design. Properly spaced stirrups distribute the shear forces evenly across the beam’s length, preventing concentrated stress points. Engineers use guidelines provided by structural codes to determine. The appropriate spacing for stirrups based on the beam’s dimensions and loading conditions.

Materials Used in Stirrup Construction:

Stirrups are typically made from reinforcing steel, commonly known as rebar. The choice of rebar material and its diameter is influenced by factors such as structural requirements. The concrete’s compressive strength, and the desired level of ductility. Stainless steel or epoxy-coated rebar may be employed in corrosive environments to enhance durability.

Applications in Different Beam Types:

Stirrups find application in various types of beams, including simply supported beams, continuous beams, and cantilever beams. Whether in buildings, bridges, or other structures, stirrups are essential elements that contribute to the overall stability and performance of the beam under different loading conditions.

Seismic Considerations:

In seismic zones, where the structure is subjected to lateral forces during an earthquake, stirrups are crucial in preventing shear failures. Properly designed and detailed stirrups contribute to the structure’s ductility and energy dissipation capacity. Ensuring its ability to withstand seismic forces without catastrophic failure.

Innovations in Stirrup Technology:

Ongoing research and advancements in construction technology continue to influence stirrup design and application. Innovations may include the use of high-strength materials, advanced numerical modeling techniques, or the incorporation of smart materials for real-time structural monitoring.

Quality Assurance and Construction Practices:

Ensuring the proper installation and alignment of stirrups during construction is essential for their effectiveness. Quality assurance measures, including inspections, testing, and adherence to construction standards. Play a crucial role in guaranteeing the reliability and performance of stirrups in beams.

Conclusion:

Stirrups in beam construction exemplify the meticulous attention to detail required in structural engineering. Their strategic placement and design significantly contribute to a beam’s ability to resist shear forces, preventing potential structural failures. As the construction industry continues to evolve, innovations in stirrup technology and construction practices will further enhance safety. Efficiency, and resilience of built structures, ensuring that beams fulfill their essential role as load-bearing elements in a diverse range of architectural and engineering projects.