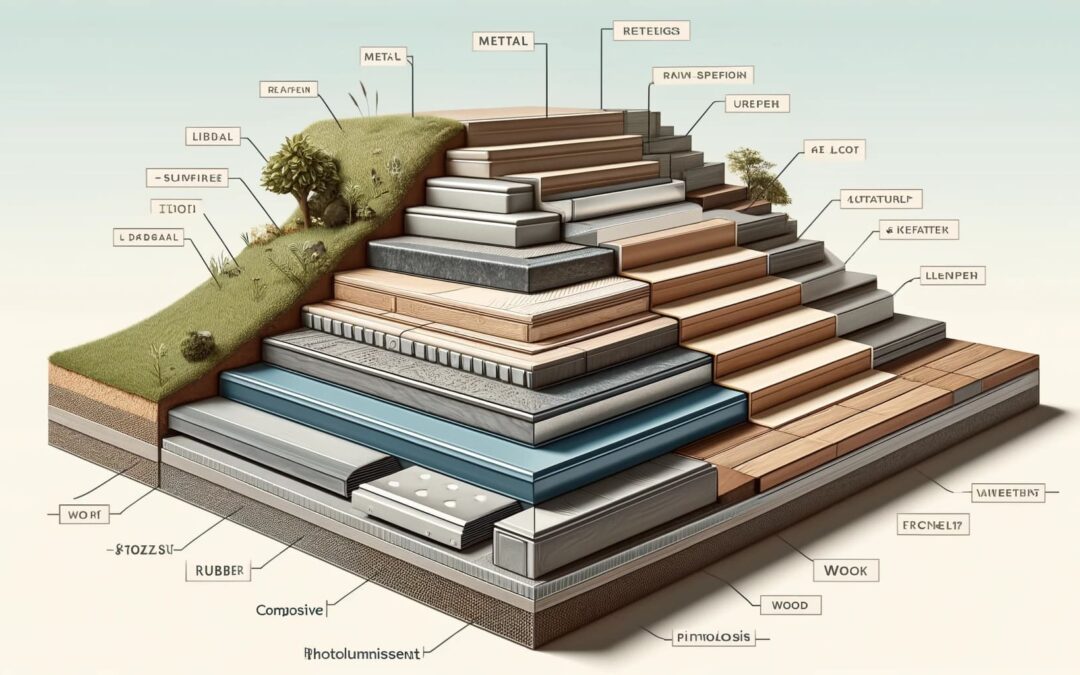

Stair nosing is an essential component of stairway design, providing not only aesthetic appeal but also contributing significantly to safety and durability. The right type of nosing can prevent slips and falls, enhance the visibility of stairs, and extend the lifespan of the stairway by protecting edges from wear and tear. This article delves into the various materials used for stair nosing and their specific applications across different environments.

1. Metal Nosing

Metal is a popular choice for stair nosing due to its durability and strength. Aluminum and stainless steel are commonly used metals that offer resistance to corrosion and wear. Metal nosing can be particularly beneficial in industrial or commercial settings where heavy foot traffic is a norm. Additionally, metal nosing often features anti-slip surfaces such as grooves or rubber inserts to enhance safety.

2. Rubber Nosing

Rubber nosing is valued for its excellent anti-slip properties and shock-absorbing qualities. It is particularly suitable for outdoor stairs or environments where moisture and slippery conditions prevail. Rubber is also a more cost-effective option and can be easily cut to fit any stair size. Its natural cushioning effect reduces the overall impact on pedestrian traffic, making it an ideal choice for schools, hospitals, and public buildings.

3. Wood Nosing

Wood nosing adds a classic and warm touch to any staircase. It is best suited for residential or office environments where aesthetics are a priority. Wood can be treated with varnishes and anti-slip coatings to enhance its durability and safety features. However, wood requires more maintenance than metal or rubber, as it is susceptible to wear, moisture, and environmental changes.

4. Composite Materials

Composite materials such as fiberglass or reinforced plastic are used for nosing to combine the benefits of multiple materials. These composites are incredibly durable, resistant to corrosion, and provide excellent traction. They are often used in specialized settings like chemical plants or coastal areas where exposure to harsh conditions is frequent. Composite nosing is also lightweight, making it easy to install and maintain.

5. Photoluminescent Nosing

Innovations in stair-nosing materials have led to the development of photoluminescent products that glow in the dark. This type of nosing is crucial for evacuation routes and emergency exits as it provides visibility in power failures or low-light conditions. Typically made from plastics or composites, photoluminescent nosing is an essential safety feature in high-rise buildings, hotels, and other public spaces.

Applications Across Different Settings

The application of stair nosing varies based on the environment and specific needs of a building:

- Commercial and Industrial Spaces: Metal and composite nosings are prevalent due to their durability and ability to withstand heavy traffic.

- Residential Buildings: Wood and rubber nosings are more common, providing safety while also complementing the interior design.

- Public and Institutional Facilities: Rubber and photoluminescent nosings are ideal for enhancing safety and accessibility.

Conclusion

Stair nosing plays a pivotal role in architecture and safety engineering. Whether it’s the robustness of metal, the comfort of rubber, the elegance of wood, or the advanced technology of photoluminescent materials, the choice of nosing should align with the building’s environmental demands and aesthetic requirements. By selecting the appropriate stair-nosing material, architects, and builders can ensure both the safety and the visual appeal of staircases, ultimately enhancing the functionality and longevity of their construction projects.