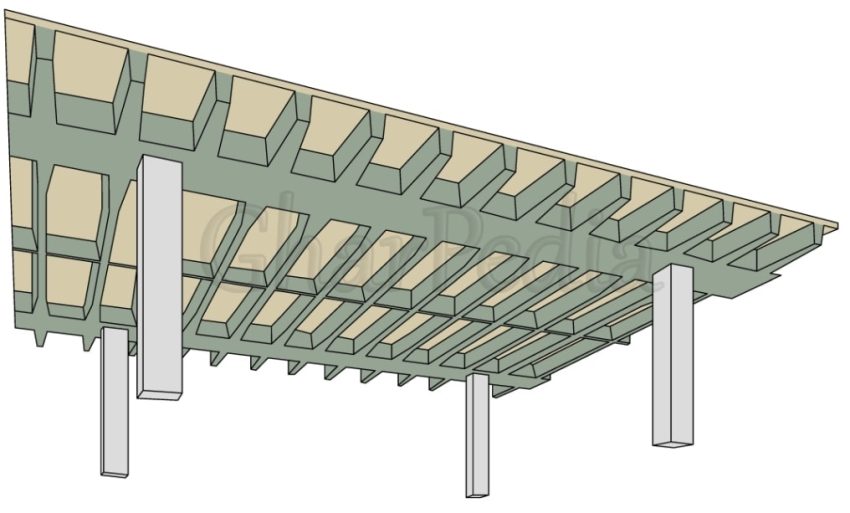

A ribbed slab is a type of reinforced concrete slab that has a series of parallel ribs running in one direction, with the top of the ribs forming the lower surface of the slab. This design allows for greater strength and flexibility in the slab while reducing its overall weight. Here is the ultimate guide to installing a ribbed slab.

Plan and Design

Before installing a ribbed slab, it is crucial to create a detailed plan and design for the project. This should include the size and thickness of the slab, the spacing and depth of the ribs, and the amount and placement of reinforcement. The plan should also consider any building code requirements and load-bearing capacity needed for the project.

Prepare the Site

The site should be prepared for the installation process, including clearing the area, leveling the ground, and installing any necessary drainage or utilities. It is important to ensure that the site is level and free of debris that can cause damage to the slab.

Install the Bearing Surface

A bearing surface should be installed to support the ribbed slab. This surface should be level and free of any debris that can cause damage to the slab. Bedding material such as sand or gravel can be used to create a smooth and level surface.

Place the Formwork

The formwork is a structure that use to create the shape of the ribbed slab. The formwork should carefully designed and constructed to ensure it can withstand the weight of the concrete and provide support for the ribs. It is important to ensure that the formwork is properly aligned and level before pouring the concrete.

Place the Reinforcement

Reinforcement is essential for providing additional strength and stability to the ribbed slab. Steel bars or mesh should place within the ribs of the slab. The reinforcement should space correctly and securely installed to ensure maximum strength and durability.

Pour the Concrete

The concrete should mixed according to the manufacturer’s instructions and poured into the formwork. It is important to ensure that the concrete evenly distributes and fills all of the ribs of the slab. A vibrator can use to ensure the concrete is properly compact and free of air pockets.

Level and Finish the Surface

Once the concrete poure, it should level and finish to ensure a smooth and even surface. A trowel or float can use to smooth the surface of the slab, and a broom or texture roller can create a non-slip surface.

Remove the Formwork

After the concrete has cure for the appropriate amount of time, the formwork can removed. It is important to ensure that the formwork is remov carefully to avoid damaging the ribs or the surface of the slab.

Inspect and Test

Before the ribb slab put into use, it is important to inspect and test it to ensure it meets safety and building code requirements. The load-bearing capacity should test, the reinforcement and surface finish inspected, and any cracks or defects checked.

In summary, installing a ribbed slab requires careful planning and attention to detail. By following these steps, you can ensure your ribbed slab is strong, durable. And meets all safety and building code requirements. It is essential to work with an experienced contractor who can help design, plan, and install the ribbed slab to ensure a successful and cost-effective project.