Plumbing systems are integral to the functionality and comfort of our homes, and the materials used play a crucial role in ensuring leak-free connections. One key consideration in plumbing design is the wall thickness of pipes and fittings. In this article, we will explore the significance of plumbing wall thickness, its impact on performance, and how it contributes to the durability and reliability of the plumbing infrastructure.

1. The Basics of Plumbing Wall Thickness:

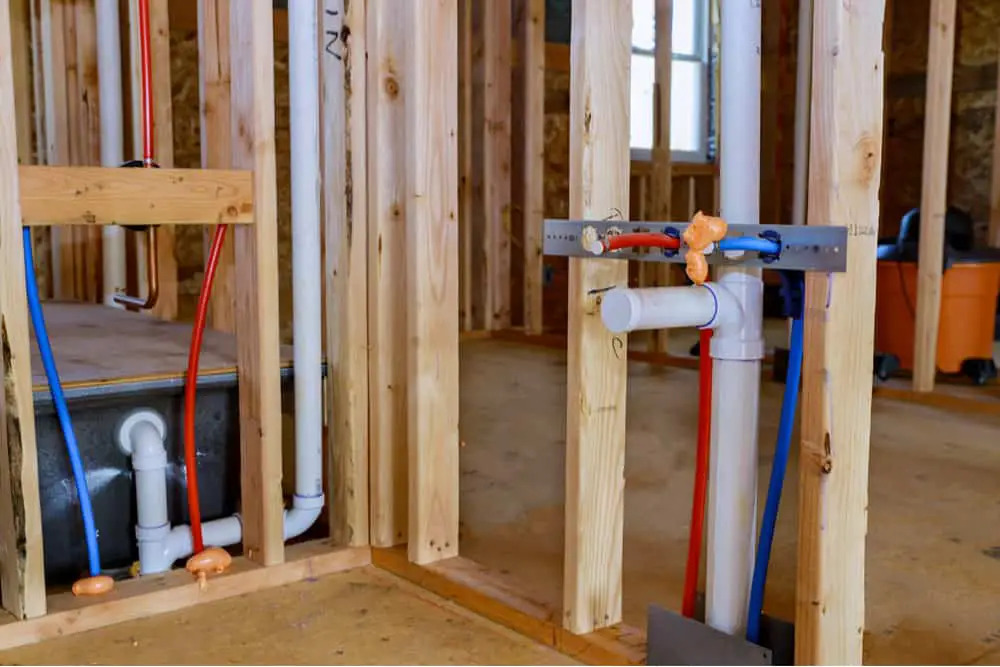

Plumbing pipes and fittings come in a variety of materials, each with its own specific wall thickness. The wall thickness refers to the measurement of the pipe or fitting’s exterior and interior walls, determining the overall strength and durability of the plumbing component. Common materials used in plumbing include copper, PVC (polyvinyl chloride), PEX (cross-linked polyethylene), and galvanized steel.

2. Copper Plumbing Wall Thickness:

Copper has long been a staple in plumbing due to its durability, resistance to corrosion, and malleability. Pipes come in various thicknesses, commonly classified as Type M, Type L, and Type K. Type M has the thinnest wall, suitable for low-pressure applications, while Type L and Type K have thicker walls, providing increased strength for higher-pressure systems. The choice of copper type depends on the specific demands of the plumbing application.

3. PVC Plumbing Wall Thickness:

PVC, a synthetic plastic polymer, is widely used in plumbing for its affordability, chemical resistance, and ease of installation. Pipes are categorized by their schedule, with Schedule 40 and Schedule 80 being the most common. Schedule 40 has a thinner wall and is suitable for standard residential applications, while Schedule 80 has a thicker wall, offering enhanced strength for more demanding environments or higher-pressure systems.

4. PEX Plumbing Wall Thickness:

PEX has gained popularity for its flexibility and ease of installation. Pipes typically come in three thickness categories: PEX-A, PEX-B, and PEX-C. The thickness of the PEX material affects its flexibility and resistance to kinking. PEX-A has the thickest wall and is known for its superior flexibility, making it easier to work with, especially in colder temperatures.

5. Galvanized Steel Plumbing Wall Thickness:

Galvanized steel pipes, once a common choice in plumbing, are known for their strength and durability. However, they have become less popular due to the tendency to corrode over time. The wall thickness of galvanized steel pipes is a critical factor in determining their longevity and resistance to corrosion. Thicker walls can provide increased durability but may also add weight to the plumbing system.

6. Impact on Pressure and Flow:

The wall thickness of plumbing pipes directly affects the pressure and flow within the system. Thicker walls generally allow pipes to withstand higher pressures without the risk of bursting or leaking. In applications where water pressure is a critical factor, such as in commercial or industrial settings, selecting pipes with appropriate walls thickness is essential to maintaining a reliable and efficient plumbing system.

7. Resistance to Leaks and Failures:

Optimal walls thickness is a key factor in preventing leaks and failures in plumbing systems. Thicker walls contribute to the overall strength and structural integrity of pipes and fittings, reducing the likelihood of cracks, fractures, or other forms of deterioration. This is especially crucial in high-pressure systems where the risk of failure is higher.

8. Temperature Considerations:

In regions with extreme temperatures, the wall thickness of plumbing materials becomes a critical consideration. Thicker walls provide better insulation against temperature fluctuations, reducing the risk of pipes freezing or becoming brittle in cold climates. Conversely, in hot climates, proper insulation can prevent heat-related issues that may compromise the integrity of the plumbing system.

9. Codes and Standards:

Building codes and industry standards play a significant role in determining the acceptable walls thickness for plumbing components. Compliance with these codes ensures that plumbing installations meet safety and performance requirements. Plumbing professionals must be well-versed in local codes to select materials with the appropriate walls thickness for a given application.

10. Future-Proofing Plumbing Systems:

As technology and building practices evolve, the future-proofing of plumbing systems becomes a consideration. Choosing materials with adequate wall thickness not only meets current needs but also allows for potential upgrades or modifications in the future. Investing in durable and adaptable plumbing infrastructure ensures longevity and reduces the need for frequent replacements.

11. Professional Guidance:

While understanding plumbing wall thickness is crucial, seeking the guidance of plumbing professionals is advisable, especially for complex installations or renovations. Professionals can assess the specific requirements of a project, recommend suitable materials, and ensure compliance with local codes and standards.

Conclusion:

Plumbing wall thickness is a fundamental aspect of designing and installing a reliable and leak-proof plumbing system. The choice of materials, along with the appropriate thickness, directly impacts the system’s ability to withstand pressure, temperature variations, and the test of time. Whether it’s copper, PVC, PEX, or galvanized steel, selecting the right wall thickness for each plumbing component is essential for creating a durable and efficient plumbing infrastructure that meets both current and future needs.